Understanding the BSPT Full Form and Its Significance in Business and Industrial Applications

In the dynamic world of industrial manufacturing and piping solutions, understanding the terminology and acronyms is essential for professionals aiming to optimize operations, ensure safety, and improve efficiency. One such crucial term is BSPT. This comprehensive article delves into the BSPT full form, its relevance in various engineering and business contexts, and how it connects to a wide array of piping components such as Tube Fittings, Ferrule Fittings, Forged Pipe Fittings, Threaded Pipe Fittings, Flanges, Valves, and more.

What Does BSPT Stand For? The Full Form Explained

The BSPT full form is an abbreviation used primarily within the industrial fittings and piping sector. While the exact expansion of BSPT can vary based on regional or industry-specific jargon, it generally refers to British Standard Pipe Thread. However, in some contexts, it may also be linked to terms like Balloucher Standard Pipe Thread or similar variants. For clarity and universal understanding, we focus on its primary interpretation:

- British Standard Pipe Thread (BSPT): A standardized thread profile used globally in piping and fluid handling systems, defined under British Standards. This thread type ensures leak-proof connections, durability, and compatibility across a variety of piping components.

In essence, BSPT embodies a specific threading style that plays a vital role in creating robust, interference-free pipe connections which are fundamental for complex industrial processes.

The Importance of BSPT Full Form in Industrial Applications

Understanding the BSPT full form is vital for engineers, technicians, and business owners involved in piping systems. The significance hinges on multiple factors:

- Standardization: Ensuring compatible fittings and components across different suppliers and regions.

- Leak Prevention: Correctly threaded pipes and fittings prevent fluid leaks, which are critical in maintaining operational safety and environmental compliance.

- Ease of Maintenance and Repair: Recognizable standards simplify the replacement process, reducing downtime and costs.

- Safety Assurance: Properly threaded systems mitigate hazards related to pipe failure under pressure or stress.

- Global Compatibility: Facilitating international trade and joint ventures through universally accepted standards.

Relevance of BSPT in Various Piping and Fitting Components

The BSPT threading style is integral to many components used in fluid handling systems. Here are some of the critical categories where BSPT specifications play a pivotal role:

Tube Fittings and Ferrule Fittings

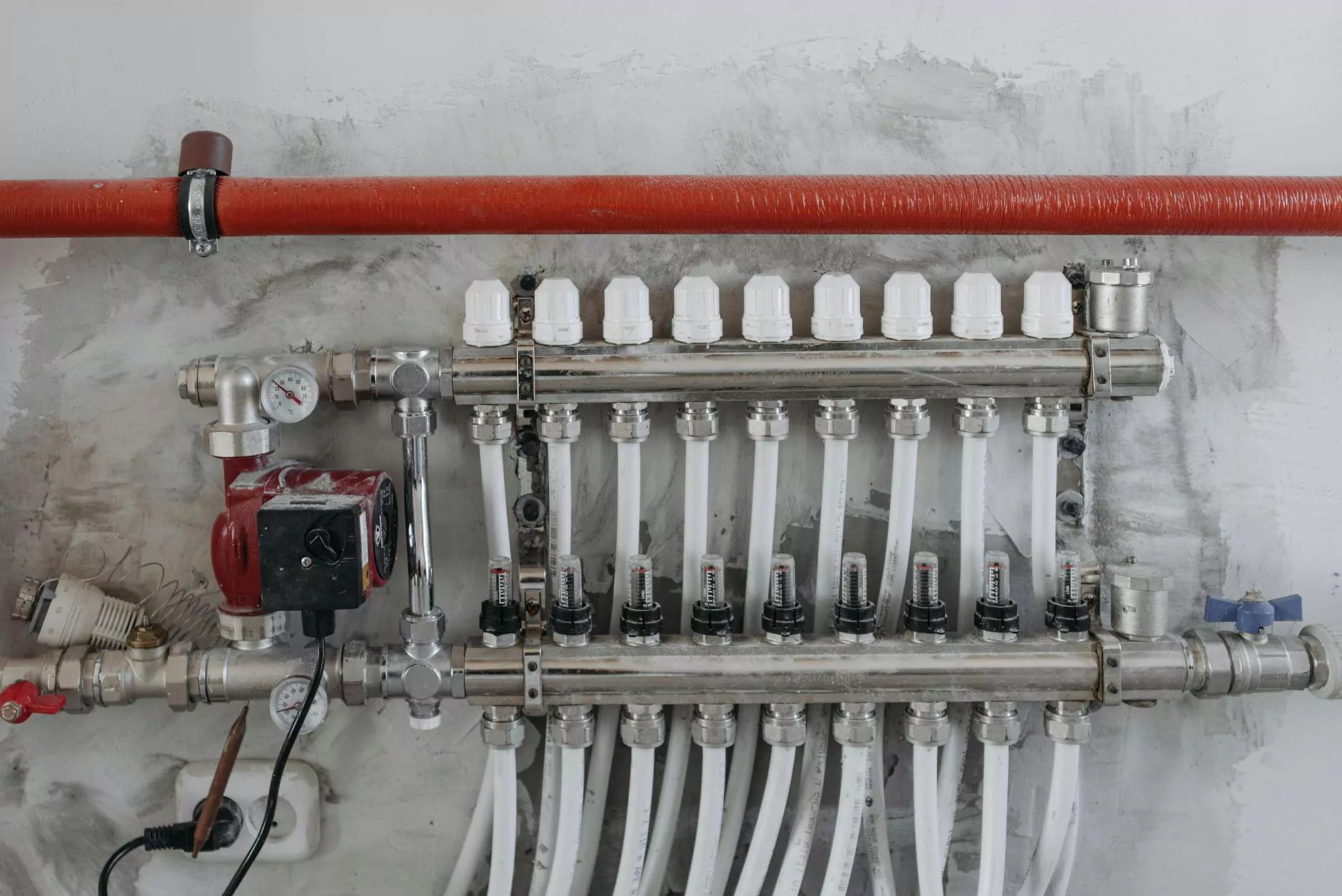

Tube fittings, including Single Ferrule and Double Ferrule Tube Fittings, are essential for creating secure connections in high-pressure systems. The threads, often adhering to BSPT standards, guarantee leak-proof and durable joints. These fittings are prevalent in industries such as oil & gas, chemical processing, and hydraulic systems.

Forged and Threaded Pipe Fittings

Forged fittings, known for their strength and versatility, utilize BSPT threads to connect pipes reliably. Threaded pipe fittings, including NPT fittings, align with the British Standard to provide tight seals, especially in high-pressure applications.

Flanges and Valves

Flanges, including BSPT-threaded types, are used to connect pipes and provide access points for inspection and maintenance. Valves such as Ball Valves, Check Valves, Needle Valves, Manifold Valves, and others, often feature threaded connections conforming to BSPT standards, facilitating secure, standardized assemblies.

Key Benefits of Using BSPT-Compliant Components in Business

- Consistency and Reliability:BSPT ensures that all fittings and pipes conform to a uniform standard, leading to consistent performance across systems.

- Cost Savings: Standardized threads reduce installation and maintenance costs by minimizing errors and mismatches.

- Enhanced Safety: Reliable connections prevent leaks and failures, safeguarding personnel and the environment.

- Ease of Procurement: Access to a wide range of compatible components across manufacturers simplifies supply chain management.

- Scalability and Flexibility: Standard fittings support system expansions or modifications with minimal hassles.

Choosing the Right Components and Ensuring Compatibility

When selecting fittings and valves for your business, especially those adhering to the BSPT standard, consider the following:

- Inspection of Standards: Always verify that the components specify conformity with British Standard Pipe Thread or relevant standards such as ISO and ANSI equivalents.

- Size Compatibility: Match the thread sizes precisely to avoid leaks or mechanical failures.

- Material Compatibility: Choose materials like stainless steel, brass, or carbon steel based on application requirements and fluid compatibility.

- Pressure Ratings: Ensure components can withstand system pressure and temperature to maintain safety and longevity.

Industry-Wide Impact of Standardization and the BSPT Full Form

The global industrial community benefits immensely from adherence to BSPT standards. It fosters international cooperation, reduces technical barriers, and promotes quality manufacturing. For example, procurement from techtubes.in, which specializes in high-quality piping fittings and valves, guarantees products that meet rigorous standards, emphasizing the importance of the BSPT full form as a quality hallmark.

Future Trends and Innovations in Piping Components and Standards

As industries progress, standards like BSPT will evolve to incorporate higher pressure tolerances, corrosion resistance, and smart monitoring capabilities. The integration of IoT-enabled valves and fittings with standard threads will further enhance system reliability and data-driven maintenance strategies, ultimately revolutionizing fluid management systems worldwide.

Summary: The Essential Role of BSPT in Modern Business Practices

In conclusion, understanding the BSPT full form is more than just academic knowledge; it is a cornerstone for ensuring safe, reliable, and efficient piping systems in various industrial sectors. From Tube Fittings and Ferrule Fittings to complex Valves and Flanges, the adherence to BSPT standards guarantees compatibility, performance, and peace of mind.

Businesses that prioritize standardization and quality control, such as those utilizing products from techtubes.in, position themselves for success in a competitive global market. Achieving excellence in piping infrastructure depends significantly on understanding the nuanced but vital role of standards like BSPT.

Contact Us for Quality BSPT-Compliant Solutions

If your business aims to elevate its piping systems with reliable, standardized fittings and valves, Techtubes provides comprehensive solutions tailored to your needs. Our extensive inventory, rigorous quality checks, and expert support make us a trusted partner in industrial fabrication and maintenance.

Final Thoughts

Knowledge of the BSPT full form and its implications is essential for anyone involved in industrial piping, fluid handling, or business procurement. By leveraging standards that promote consistency, safety, and efficiency, companies can ensure operational excellence and sustained growth. Embrace the standards, select the right components, and optimize your business processes today.