Understanding the Impact of China CNC Turning Parts on Global Manufacturing

In the rapidly evolving world of manufacturing, China CNC turning parts have emerged as a cornerstone of modern production techniques. Businesses looking for precision and efficiency have increasingly turned to the advanced capabilities offered by CNC (Computer Numerical Control) technology. This article explores the significance of CNC turning parts manufactured in China, their benefits, and the crucial role they play in various industries.

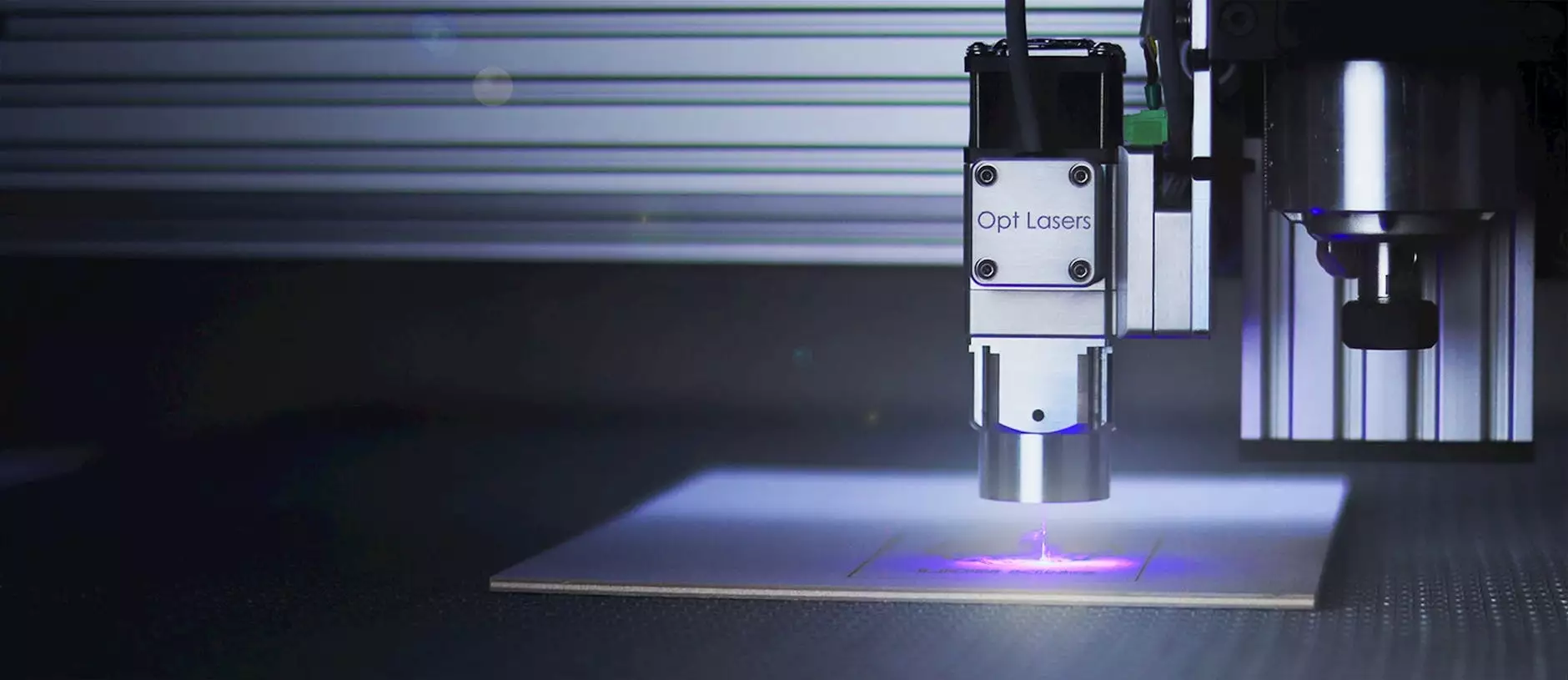

The Basics of CNC Turning Parts

CNC turning is a manufacturing process that involves rotating a workpiece while a cutting tool remains stationary. This method is highly effective for producing symmetrical parts with intricate designs. The China CNC turning parts market has grown significantly due to its ability to meet diverse manufacturing needs.

What Makes CNC Turning So Efficient?

- Precision: CNC machines are programmed to create parts with exceptional accuracy, minimizing errors.

- Automation: The automation of the CNC process allows for continuous production with reduced labor costs.

- Material Versatility: CNC turning can be applied to a variety of materials, including metals, plastics, and composites.

- Complex Shapes: The advanced programming allows for the creation of complex geometries that would be challenging or impossible to achieve manually.

The Growth of CNC Machining in China

China has positioned itself as a global leader in manufacturing, particularly in CNC machining. The country's robust infrastructure, skilled workforce, and competitive pricing have contributed to its prominence in producing CNC turning parts.

Quality Assurance in China CNC Turning Parts

Quality is paramount in manufacturing, and China CNC manufacturers have adopted rigorous standards to ensure their products meet international specifications. Many factories are certified with ISO standards and utilize advanced quality control methods:

- Inspection Techniques: Manufacturers use a variety of inspection techniques, including coordinate measuring machines (CMM) and laser scanning technology.

- Regular Audits: Factories are regularly audited to maintain compliance with global quality standards.

- Customer Feedback: Continuous improvement processes are informed by customer feedback, ensuring that products consistently meet market demands.

Advantages of Sourcing CNC Turning Parts from China

Choosing to source China CNC turning parts offers numerous advantages for companies in need of reliable and high-quality components:

1. Cost-Effectiveness

One of the most appealing aspects of sourcing parts from China is the significant cost savings. The country’s low labor costs, combined with economies of scale, mean that businesses can obtain high-quality components at competitive prices.

2. Speedy Production

Chinese manufacturers are known for their ability to ramp up production quickly. With advanced CNC machinery and well-trained staff, companies can expect shorter lead times for large orders, ensuring that projects stay on schedule.

3. Access to Advanced Technology

Many Chinese manufacturers invest heavily in the latest CNC technology, allowing them to produce parts with advanced features and complexities. This access to cutting-edge technology enables clients to innovate and differentiate their products in the market.

Industries Benefiting from China CNC Turning Parts

The applications of CNC turning parts extend to a wide range of industries. Here are some key sectors that benefit significantly from these components:

1. Aerospace and Defense

In the aerospace sector, precision is non-negotiable. China CNC turning parts are used in the manufacture of components such as turbine blades, landing gear, and structural elements, where accuracy directly influences safety and performance.

2. Automotive

Automotive manufacturers rely on CNC turning parts for producing engine components, transmission parts, and more. The ability to produce lightweight, high-strength parts efficiently is essential in today's competitive automotive landscape.

3. Medical Devices

The medical field demands the highest level of precision and reliability. China CNC turning parts are incorporated into surgical instruments, implants, and diagnostic equipment, ensuring that these critical devices function as intended.

Choosing the Right CNC Manufacturer in China

Not all manufacturers are created equal. When selecting a supplier for China CNC turning parts, consider the following factors:

1. Reputation and Experience

Look for manufacturers with a proven track record in the industry. Established companies are more likely to have the experience necessary to produce high-quality parts consistently.

2. Certifications and Compliance

Ensure that potential suppliers comply with international standards such as ISO 9001. This will give you confidence in their quality management systems.

3. Communication

Effective communication is crucial for successful collaboration. Choose a supplier that is responsive and understands your specific needs and requirements.

The Future of CNC Turning Parts from China

As the global economy continues to evolve, the demand for China CNC turning parts is expected to grow. Advancements in technology, such as automation and Industry 4.0, will enhance efficiency and quality, making CNC machining even more attractive to manufacturers worldwide.

1. Emphasis on Sustainability

With the world becoming more conscious about environmental impact, manufacturers are exploring sustainable practices. CNC producers in China are looking to adopt eco-friendly materials and processes, reducing waste and energy consumption.

2. Enhanced Customization Capabilities

As markets demand more tailored solutions, CNC manufacturers are starting to offer greater customization options. This flexibility allows businesses to create unique parts that meet specific needs without significant delays.

Conclusion: The Indispensable Role of China CNC Turning Parts in Manufacturing

In conclusion, China CNC turning parts are vital to modern manufacturing, providing solutions that combine precision, cost-effectiveness, and innovation. As industries across the globe continue to demand higher quality and efficiency, the role of CNC turning parts produced in China will only grow stronger.

For businesses looking to elevate their manufacturing capabilities, partnering with a reliable supplier like DeepMould.net can be a strategic move. With a commitment to quality and customer satisfaction, DeepMould.net is here to support your manufacturing needs with top-tier CNC turning parts.